Solution

Inleash DurabilityAdverting Industries

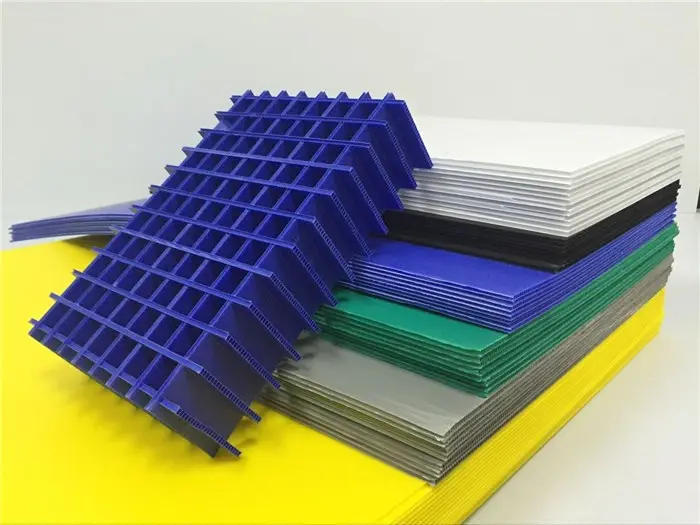

The advertising industry extensively uses PP (Polypropylene) corrugated sheets for a variety of promotional and display purposes due to their lightweight, durable, and versatile nature. These sheets are favored for creating signage, display boards, and promotional materials that are both cost-effective and durable, making them ideal for both indoor and outdoor advertising campaigns.

PP corrugated sheets are widely used for billboards, point-of-purchase (POP) displays, and event signage because they are easy to print on and can withstand various environmental conditions, including UV exposure, rain, and wind. Their waterproof and weather-resistant qualities make them especially suitable for outdoor advertising, ensuring that the promotional messages stay intact and vibrant for an extended period.

Plastic & Palette Industries

In the plastic and pallet industries, PP (Polypropylene) corrugated sheets play a crucial role in protective packaging, storage solutions, and material handling. Known for their durability, lightweight structure, and moisture resistance, these sheets are used to enhance the efficiency of palletization and transport processes by safeguarding products and improving load stability.

PP corrugated sheets are often used as layer pads, placed between stacked items on pallets to distribute weight evenly and prevent damage during storage and shipping. Their rigid yet flexible nature provides excellent support to fragile or irregularly shaped plastic products, ensuring they remain secure throughout handling and transit. These sheets can also act as dividers between products to prevent friction, scratches, and breakage.

Bottles & Beverage Industries

The bottles and beverage industry leverages PP (Polypropylene) corrugated sheets for a variety of purposes due to their durability, lightweight nature, and moisture resistance. These sheets are primarily used in packaging, storage, and transportation of beverage bottles, offering a protective solution that minimizes damage during handling and shipping.

In the packaging process, PP corrugated sheets serve as dividers and separators between layers of bottles, preventing movement and reducing the risk of breakage. The sheets' structural rigidity ensures that bottles remain securely in place, which is especially important for fragile glass bottles and delicate plastic containers.

Electronic Industries

The electronic industry relies heavily on PP (Polypropylene) corrugated sheets for packaging, protection, and transportation of sensitive electronic components. Due to their lightweight, durable, and anti-static properties, PP corrugated sheets offer an ideal solution for safely handling delicate electronic devices, such as circuit boards, microchips, and various components prone to damage from static electricity, moisture, and impact.

PP corrugated sheets are used as protective packaging material for electronic goods during transit. They serve as dividers, inserts, and trays, ensuring that electronic parts are separated and do not move around, preventing scratches, dents, or short-circuiting. Their structural rigidity helps safeguard fragile items, while their moisture-proof nature shields components from humidity, which could lead to corrosion or malfunction.

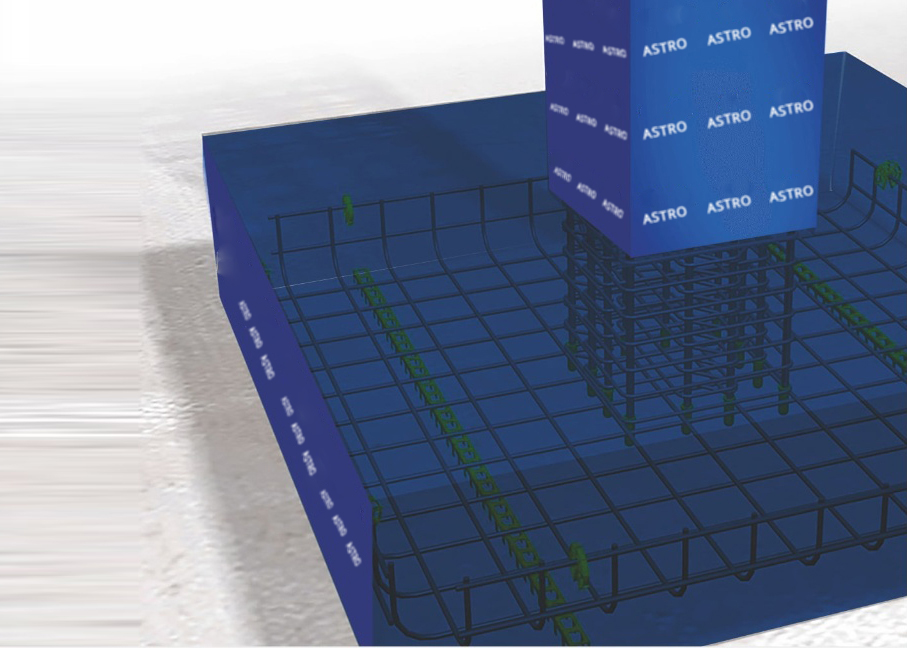

Building & Construction Industries

In the building and construction industries, PP (Polypropylene) corrugated sheets are highly valued for their versatility, durability, and lightweight properties. These sheets are commonly used for temporary protection, formwork, insulation, and signage during construction projects, offering a cost-effective solution for safeguarding surfaces and materials on-site.

PP corrugated sheets are often utilized as floor protection to shield newly laid tiles, hardwood, or concrete from damage during the construction or renovation process. Their impact-resistant and waterproof properties ensure that surfaces are protected from scratches, debris, spills, and heavy foot traffic.

Industrial Packaging Industries

In the industrial packaging sector, PP (Polypropylene) corrugated sheets are extensively used due to their strength, lightweight nature, and versatility in protecting and transporting a wide range of products. These sheets are designed to provide protective packaging, separation, and support for items across various industries, from automotive components to electronics, machinery, and chemicals.

PP corrugated sheets are commonly used as layer pads, dividers, and inserts within packaging to separate products and prevent shifting during transportation. Their impact resistance and structural rigidity ensure that items remain stable and secure, reducing the risk of damage or breakage, especially for delicate or high-value goods.

Agriculture Packaging Industries

In the agriculture packaging industry, PP (Polypropylene) corrugated sheets play a vital role due to their durability, lightweight nature, and resistance to moisture and chemicals. These sheets are widely used for packaging, storage, and transportation of agricultural products such as fruits, vegetables, seedlings, and plants, providing reliable protection throughout the supply chain.

PP corrugated sheets are commonly used to create custom packaging solutions such as foldable boxes, trays, and dividers. These lightweight, yet sturdy structures protect produce from damage during handling, transportation, and storage. Their impact resistance ensures that delicate items like fruits and vegetables remain safe from bruising or crushing, while their moisture-proof properties safeguard produce from humidity or water exposure, preserving freshness.

Tote & Stationery Industries

In the tote and stationery industries, PP (Polypropylene) corrugated sheets are increasingly utilized for their lightweight, durable, and versatile properties, making them an ideal choice for a variety of applications ranging from packaging to product organization. These sheets serve as an excellent solution for creating customized storage containers, dividers, and protective packaging for stationery products and tote bags.

In the tote industry, PP corrugated sheets are often used to manufacture sturdy yet lightweight totes and carrying cases. Their robust structure provides the necessary support for holding various items securely, whether for personal use, office organization, or travel. The sheets can be easily cut, folded, and assembled into different shapes, allowing manufacturers to create a wide range of tote designs tailored to specific needs.

Steel & Metal Industries

In the steel and metal industries, PP (Polypropylene) corrugated sheets are essential for protective packaging, handling, and storage of various metal components and products. Known for their lightweight, durable, and moisture-resistant properties, these sheets provide effective solutions to safeguard metal items during transportation and storage while minimizing the risk of damage.

PP corrugated sheets are commonly used as protective liners and cushioning materials within packaging solutions for steel and metal products. They serve to prevent scratches, dents, and other forms of damage that can occur during handling and shipping. When used as layer pads, these sheets help distribute weight evenly and absorb shock, ensuring that heavier items like steel plates, beams, or fabricated metal parts remain secure and undamaged during transit.

Textile Industries

In the textile industry, PP (Polypropylene) corrugated sheets are increasingly utilized for their durability, lightweight nature, and moisture resistance, making them ideal for various applications related to the storage, packaging, and transportation of textile products. These sheets play a crucial role in protecting fabrics, garments, and other textile goods from damage, dust, and moisture during handling and shipping.

PP corrugated sheets are commonly used as protective packaging materials for finished textile products, such as clothing, linens, and upholstery. They serve as dividers and liners within boxes or containers, ensuring that individual items remain separate and preventing wrinkling, creasing, or other damage during transport. Their sturdy structure provides essential support, helping to maintain the shape and quality of delicate fabrics.

Natural Stone & Marble Industries

In the natural stone and marble industries, PP (Polypropylene) corrugated sheets are essential for providing effective packaging, protection, and support for heavy and fragile stone products. Known for their lightweight, durable, and moisture-resistant properties, these sheets offer reliable solutions for safeguarding natural stone and marble tiles, slabs, and other finished products during transportation and storage.

PP corrugated sheets are commonly used as protective packaging materials to cushion and support stone products. They serve as layer pads and dividers within crates and pallets, preventing direct contact between individual pieces and reducing the risk of scratches, chips, or cracks during handling and transit. Their structural rigidity helps maintain stability, allowing for safe stacking of heavy stone products without compromising their integrity.

Pharma Industries

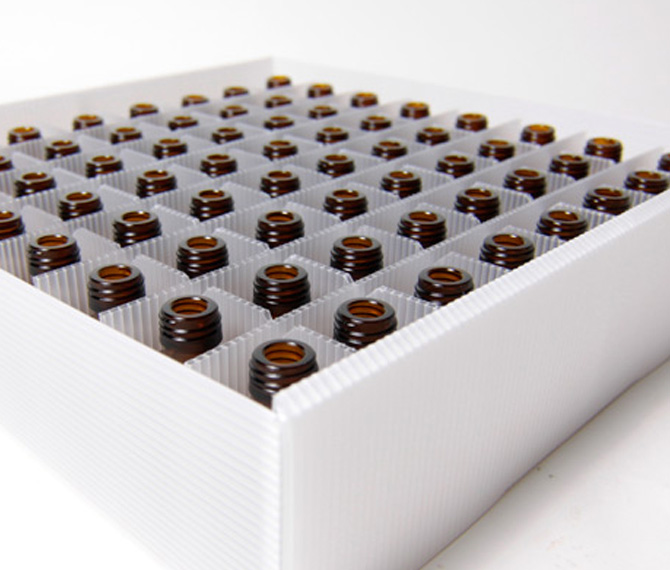

In the pharmaceutical industry, PP (Polypropylene) corrugated sheets are increasingly utilized for their durability, lightweight, and moisture-resistant properties, making them ideal for various applications related to the packaging, protection, and storage of pharmaceutical products. These sheets play a crucial role in ensuring the safety, integrity, and quality of medicines, medical devices, and other healthcare products during transportation and storage.

PP corrugated sheets are commonly used as protective packaging materials for pharmaceutical products, providing a sturdy and secure environment that helps prevent damage from external factors. They serve as dividers, inserts, and cushioning materials within packaging to keep individual items separated, reducing the risk of breakage, contamination, or other damage during transit. This is particularly important for fragile products, such as glass vials, syringes, and tablets.

Food Industries

In the food industry, PP (Polypropylene) corrugated sheets are widely utilized for their durability, lightweight nature, and moisture resistance, making them an ideal choice for various applications related to food packaging, storage, and transportation. These sheets play a crucial role in ensuring the safety, quality, and integrity of food products while adhering to stringent health and safety standards.

PP corrugated sheets are commonly used as protective packaging materials for a wide range of food items, including fruits, vegetables, meats, dairy products, and baked goods. They serve as dividers, trays, and containers that help separate and organize food products, preventing damage and contamination during transport and storage. Their sturdy structure provides essential support, helping to maintain the shape and quality of delicate items like fruits and pastries.

Trees & Plants Industries

The trees and plants industries use PP (Polypropylene) corrugated sheets for a variety of applications, primarily for protection, packaging, and transportation of saplings, potted plants, and delicate foliage. Due to the lightweight, durable, and weather-resistant properties of PP corrugated sheets, they are a preferred material in ensuring the safe handling of plants throughout their journey from nurseries to retail outlets or planting sites.

In plant nurseries, these sheets are commonly used as protective covers and dividers during the shipping process, preventing pots and plants from shifting or getting damaged during transport. Their rigid structure keeps the plants in place, while their moisture-resistant properties protect the packaging from exposure to water, rain, and soil, ensuring that the plants arrive in optimal condition.